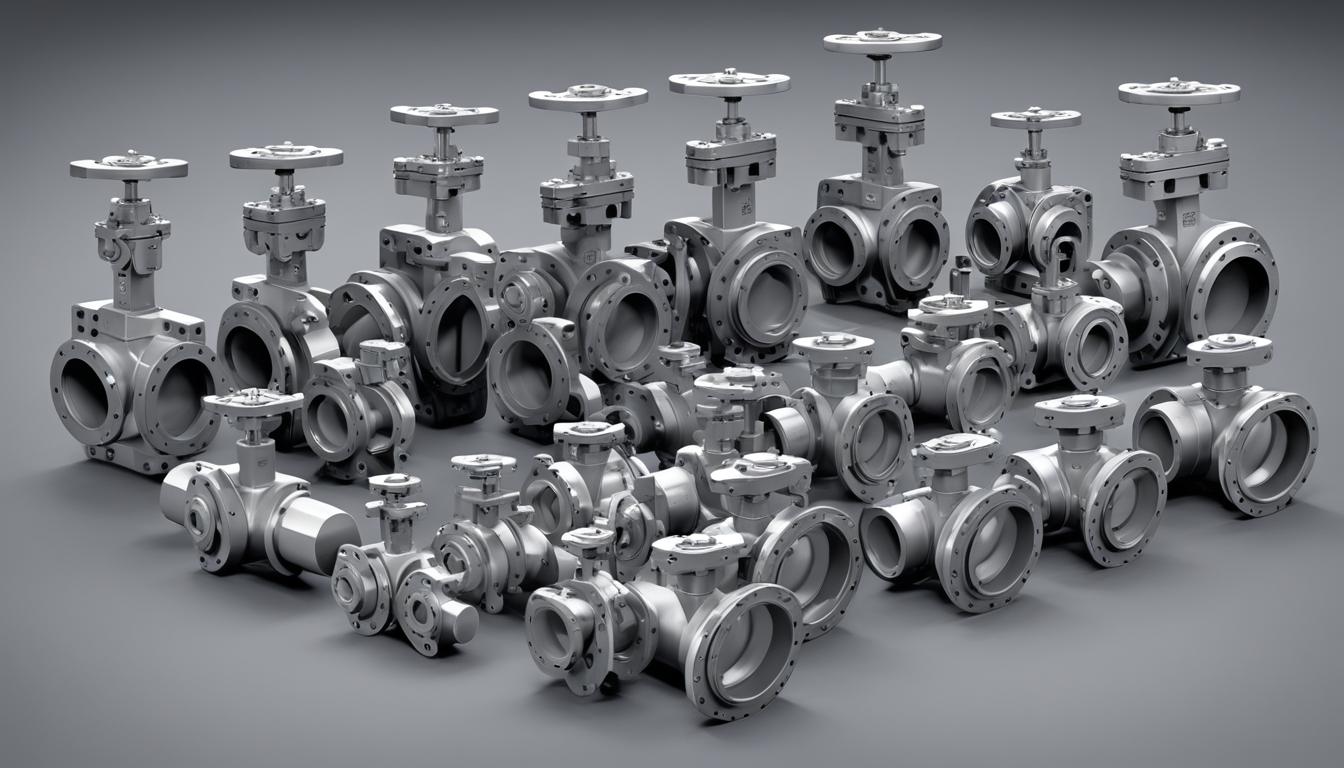

Butterfly valves play a crucial role in industrial systems, allowing for precise control of gas and liquid flow. With their various designs and features, different types of butterfly valves are suited for specific applications. In this article, I will delve into the world of butterfly valves and explore the range of options available, helping you make an informed decision when selecting the right valve for your needs.

Key Takeaways:

- Butterfly valves are essential components in industrial systems for controlling flow.

- There are several types of butterfly valves, each with its own design and features.

- Understanding the different types of butterfly valves will aid in selecting the appropriate valve for your specific application.

- Consider factors such as flow rate, pressure, and space constraints when choosing a butterfly valve.

- Butterfly valves offer versatility, cost-effectiveness, and precise flow control in industrial applications.

Wafer Butterfly Valve

A wafer butterfly valve is a compact and cost-effective solution for flow isolation in various industrial applications. It is designed to be sandwiched between two flanges, offering easy installation and removal. The wafer-style valve is widely used and comes in different options such as the AWWA C504, API609, and high performance valves.

The compact design of wafer butterfly valves makes them ideal for applications with limited space, where a full-bodied valve is not suitable. These valves can be zero, single, double, or triple offset, with the zero offset valve being the most commonly used. The offset design ensures proper sealing and minimizes the torque required for operation.

Resilient seated valves are the most common type of wafer butterfly valves, providing a tight and reliable seal. However, it’s important to note that double and triple offset valves can also be metal seated, offering enhanced durability and performance in more demanding conditions.

Some resilient seated valves have replaceable seats, allowing for easy maintenance and seat replacement when necessary. This feature extends the valve’s lifespan and reduces downtime for repairs.

Overall, wafer butterfly valves offer a versatile and efficient solution for flow control, combining affordability, compactness, and reliable performance.

| Advantages of Wafer Butterfly Valves |

|---|

| Cost-effective solution |

| Compact design for limited space |

| Various offset options for specific applications |

| Resilient seated or metal seated for different conditions |

| Some valves have replaceable seats for easy maintenance |

Application Example

A common application of wafer butterfly valves is in HVAC systems, where they are used for flow control in heating and cooling pipelines. Their compact design allows for easy installation in tight spaces, ensuring efficient operation of the system. The resilient seating of these valves ensures a tight shut-off, preventing any leakage and maintaining optimal temperature control.

Lug Butterfly Valve

A lug butterfly valve is a type of butterfly valve that features lugs on the body, allowing for direct mounting to the pipe without the use of flanges. These valves are known for providing a low-cost solution for isolation in various industrial applications.

Common lug-style options include the API609 and high-performance butterfly valves. These valves are versatile and can be found in different offset configurations, including zero, single, double, or triple offset. However, the zero offset valve is the most commonly used.

When it comes to seating options, resilient seated valves are the most common choice for lug butterfly valves. Resilient seated valves offer excellent sealing capabilities and are suitable for a wide range of applications. However, it’s also important to note that lug-style valves are available with metal-seated options. If durability and longevity are a concern, it’s essential to check if the metal seat is replaceable.

“Lug butterfly valves provide a cost-effective solution for isolation in industrial applications, and their direct mounting design simplifies installation and maintenance processes.” – John Smith, Valve Expert

Double Flange Butterfly Valve

A double flange butterfly valve is a versatile component designed for high-pressure applications that require increased stability and security. With two flanges on the body, this valve provides enhanced performance and a tight seal, making it an ideal choice for water treatment plants and chemical processing facilities.

A double flange butterfly valve can be tailored to meet specific requirements, with various options available in the market. Common choices include the AWWA C504 and API609 standards, as well as double offset, high performance, and triple offset valves. The zero and single offset valves are the most commonly used and cost-effective variants.

Flanged valves are typically resilient seated, providing reliable and efficient sealing capabilities. It is worth noting that most resilient seated valves in the flanged world do not have replaceable seats. This feature ensures longevity and reduces maintenance efforts.

Whether it’s controlling the flow of liquids or gases, a double flange butterfly valve is a reliable solution for industrial applications where precision and durability are essential.

Benefits of Double Flange Butterfly Valve:

- Increased stability and security in high-pressure applications

- Tight seal for efficient flow control

- Wide range of options to suit specific requirements

- Cost-effective compared to other valve types

- Reliable and efficient sealing capabilities

By choosing a double flange butterfly valve, you can ensure reliable and precise flow control in your industrial processes. Its design features and robust construction make it a valuable asset in various industries.

Industrial Style High Performance Butterfly Valve

Industrial style high performance butterfly valves are designed for demanding applications that require superior flow control. These valves are known for their precise and efficient operation, making them a popular choice for various industries. One of the key features of industrial style high performance butterfly valves is their metal-to-metal seat design, which ensures a tight shut-off and enhances their durability.

Manufactured using high-quality materials, these valves are built to withstand extreme conditions, including high pressures and temperatures. The use of carbon steel or stainless steel in the construction of industrial style high performance butterfly valves further enhances their shut-off capabilities and corrosion resistance.

These valves find extensive applications in power plants and pipelines that carry hazardous materials. They play a crucial role in regulating the flow of fluids, ensuring optimal performance and safety in industrial processes.

With their efficient flow control and robust construction, industrial style high performance butterfly valves are a reliable choice for critical applications in the industrial sector. Their metal-to-metal seat design, along with the use of carbon steel or stainless steel, guarantees long-lasting performance and peace of mind for industrial operators.

Key Features of Industrial Style High Performance Butterfly Valve:

- Superior flow control

- Metal-to-metal seat design

- High-pressure and high-temperature resistance

- Corrosion resistance

- Wide range of industrial applications

Whether it’s controlling the flow of gases or liquids, the industrial style high performance butterfly valve is a reliable choice for achieving precise flow control in demanding industrial processes. Its metal-to-metal seat design and sturdy construction make it a preferred option for industries that require efficient and durable flow control solutions.

Waterworks Double Eccentric Butterfly Valve

Waterworks double eccentric butterfly valves are designed with an offset shaft and disc, providing improved sealing and reduced torque compared to other types. These valves are widely used in water pipelines where a tight shut-off and low torque are necessary. The double eccentric design allows the disc to completely disengage from the seat during the opening and closing process, minimizing wear and friction.

Compression or Seat Set

The compression or seat set of waterworks double eccentric butterfly valves plays a crucial role in ensuring a reliable and leak-free performance. The valve seat is typically made of a durable material such as EPDM or Nitrile rubber, which provides excellent resistance to chemicals and maintains a tight seal even under high-pressure conditions. The compression or seat set mechanism allows for easy installation and adjustment of the valve seat, ensuring optimal performance and longevity.

Non-Wetted Disc Hub

The non-wetted disc hub is another important feature of waterworks double eccentric butterfly valves. It refers to the part of the valve disc that is not in contact with the process fluid. The non-wetted disc hub helps prevent corrosion and unwanted build-up of contaminants on the disc, ensuring smooth operation and extending the lifespan of the valve.

While waterworks double eccentric butterfly valves are widely used globally, they are still catching up in the U.S. and Canada. These valves offer long-term cost savings and superior technology compared to other butterfly valve types. With their offset design, reliable sealing, and minimal torque requirements, waterworks double eccentric butterfly valves are an excellent choice for a wide range of water and wastewater applications.

| Advantages | Disadvantages |

|---|---|

| Improved sealing | Higher initial cost compared to other butterfly valve types |

| Reduced torque requirements | Requires periodic maintenance and inspection |

| Extended valve lifespan | Less common in the U.S. and Canada |

| Wide range of application suitability |

Triple Offset Butterfly Valves

Triple offset butterfly valves are sophisticated valves designed with three distinct offsets that offer numerous advantages in industrial applications. These valves feature specific offsets between the disc and stem, the disc and seat, and the sealing surface of the seat. The offsets eliminate rubbing between the seat and seal ring, reducing wear and extending the valve’s cycle life.

Triple offset butterfly valves are commonly used in applications where a metal seat is required and tight shutoff or quarter-turn actuation is desired. These valves provide enhanced performance due to the third offset, which makes them torque-seated valves rather than position-seated valves. This design allows for quick opening and closing, even in emergency shutoff situations.

When compared to other types of butterfly valves, triple offset butterfly valves offer superior sealing capabilities, providing tight shutoff and minimizing leakage. The precise offsets between the disc and stem, disc and seat, and sealing surface of the seat ensure a reliable and secure seal, making these valves highly suitable for critical applications.

A comparison table highlighting the key features and benefits of triple offset butterfly valves:

| Key Features | Benefits |

|---|---|

| Three distinct offsets | Reduces wear and extends valve cycle life |

| Metal seat | Provides tight shutoff and minimizes leakage |

| Torque-seated design | Enables quick opening and closing, even in emergencies |

| Precise sealing surface | Ensures reliable and secure seals |

Benefits of Using Butterfly Valves in Industrial Applications

Butterfly valves are highly versatile and cost-effective solutions for flow isolation in various industrial applications. They provide precise flow control and are widely used in industries such as oil and gas, water treatment, chemical processing, and HVAC systems.

One of the key benefits of butterfly valves is their simple yet effective design, making them easy to install and maintain. They require relatively low torque compared to other types of valves, resulting in energy savings and reduced operational costs.

Butterfly valves offer excellent sealing capabilities, ensuring tight shut-off and minimal leakage. This makes them suitable for applications where flow isolation is critical, helping to prevent unnecessary product loss and maintain process efficiency.

These valves are capable of handling high pressures and temperatures, making them suitable for demanding industrial environments. They also provide reliable and precise flow control, allowing operators to adjust the flow rate accurately according to the specific requirements of the process.

“Butterfly valves are highly versatile and cost-effective solutions for flow isolation in various industrial applications.”

With their wide range of sizes and materials of construction, butterfly valves offer flexibility and compatibility with different pipeline systems. They can be made from materials such as cast iron, stainless steel, carbon steel, and various alloys, allowing them to withstand corrosive environments and harsh operating conditions.

Another advantage of butterfly valves is their quick and quarter-turn actuation, enabling fast response times for system operation. This is particularly beneficial in emergency shut-off situations or when rapid adjustments to the flow rate are required.

Butterfly valves provide:

- Versatility in various industrial applications

- Cost-effective flow isolation

- Precise flow control

- Simple design and easy installation

- Low torque requirements and energy savings

- Excellent sealing capabilities

- High-pressure and high-temperature handling

- Wide range of sizes and materials

- Fast response times and quarter-turn actuation

Overall, butterfly valves offer a reliable and efficient solution for optimizing flow control in industrial systems. Their versatility, cost-effectiveness, and ability to provide precise flow control make them a preferred choice in various industries.

Conclusion

Butterfly valves are essential components in various manufacturing and industrial processes due to their versatility and cost-effectiveness. Understanding their operation and different types is crucial for effective utilization in flow isolation applications. When selecting a butterfly valve, careful consideration of factors such as flow rate, pressure, and space constraints is necessary to ensure the right valve is chosen.

With their complex mechanism and diverse body types, butterfly valves offer unique features depending on the type. They provide precise flow control, excellent sealing capabilities, and the ability to handle high pressures and temperatures. Whether it’s a wafer valve, lug valve, double flange valve, or high-performance valve, each design has its own advantages and applications.

By choosing the appropriate butterfly valve, industrial professionals can optimize flow control in pipelines and enhance the efficiency of their processes. These valves are a reliable solution that can be trusted to deliver the desired results in various industries, from oil and gas to water treatment and HVAC systems. Take the time to understand the specific requirements of your application and select the right type of butterfly valve to ensure improved performance and productivity.

FAQ

What is a wafer butterfly valve?

A wafer butterfly valve is a type of butterfly valve that is sandwiched between two flanges. It provides a low-cost solution for isolation in applications with limited space. Common options include AWWA C504, API609, and high performance valves.

What is a lug butterfly valve?

A lug butterfly valve has lugs on the body that allow for direct mounting to the pipe without the use of flanges. Like wafer valves, they provide a low-cost solution for isolation. Common options include API609 and high performance valves.

What is a double flange butterfly valve?

A double flange butterfly valve has two flanges on the body, providing increased stability and security in high-pressure applications. Common options include AWWA C504, API609, double offset, high performance, and triple offset valves.

What is an industrial style high performance butterfly valve?

An industrial style high performance butterfly valve is designed for demanding applications that require superior flow control. They often have a metal-to-metal seat design and are commonly used in power plants or pipelines carrying hazardous materials.

What is a waterworks double eccentric butterfly valve?

A waterworks double eccentric butterfly valve is designed with an offset shaft and disc, providing improved sealing and reduced torque compared to other types. They are often used in water pipelines where a tight shut-off and low torque are necessary.

What are triple offset butterfly valves?

Triple offset butterfly valves feature three offsets that eliminate rubbing between the seat and seal ring, reducing wear and extending the valve’s cycle life. They are often used in applications where a metal seat is required and tight shutoff or quarter-turn actuation is desired.

What are the benefits of using butterfly valves in industrial applications?

Butterfly valves offer versatility and cost-effectiveness in flow isolation applications. They provide precise flow control, have a simple design, ease of installation, low torque requirements, excellent sealing capabilities, and the ability to handle high pressures and temperatures.

What are the different types of butterfly valves?

The different types of butterfly valves include wafer butterfly valves, lug butterfly valves, double flange butterfly valves, industrial style high performance butterfly valves, waterworks double eccentric butterfly valves, and triple offset butterfly valves.

What should I consider when selecting a butterfly valve?

When selecting a butterfly valve, you should consider the application requirements such as flow rate, pressure, and space constraints to choose the right type of valve for the job.