Discover the different types of laser cutters. Choosing the right laser cutter depends on your needs. This guide covers CO2, fiber, and solid-state lasers, highlighting their strengths for various materials and projects.

What Are Laser Cutters?

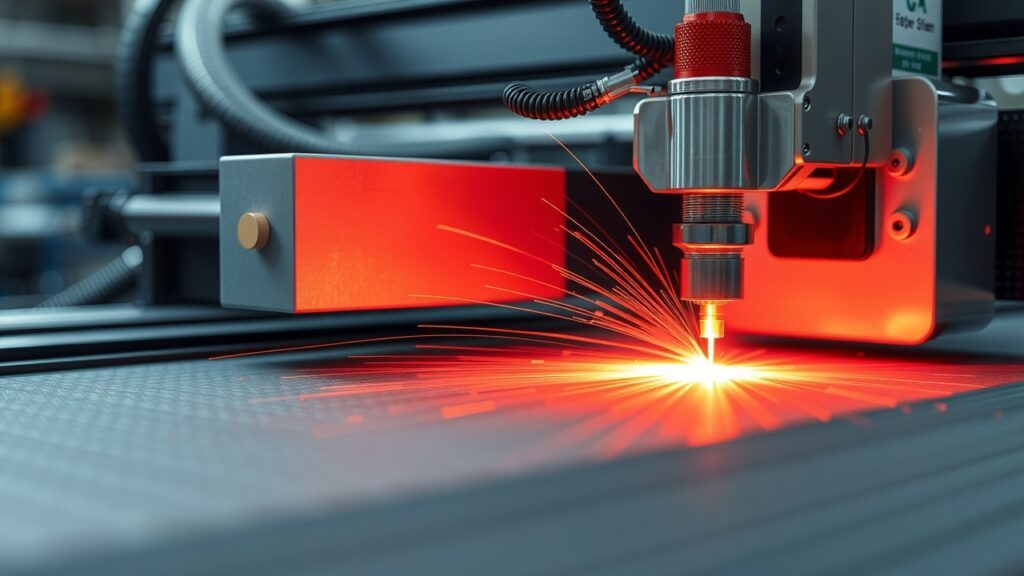

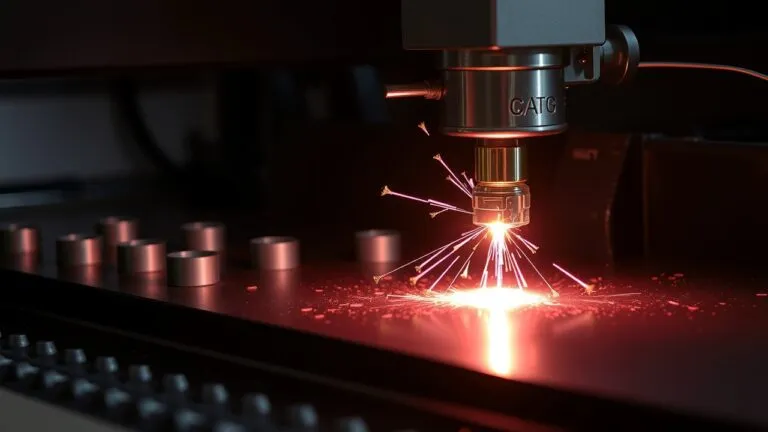

Laser cutters are machines that use laser cutting technology to cut and engrave materials accurately. They work by directing a focused beam of light onto a material, heating it until it melts or vaporizes. This process allows for clean cuts and detailed designs.

The laser cutting process is versatile. It can be found in various industries, such as manufacturing, art, and crafts. By changing settings like power and speed, users can work with different materials, including wood, acrylics, metals, and fabrics. Laser cutter machines are essential for both professional use and DIY projects.

Why Do Different Types of Laser Cutters Matter?

Choosing the right laser cutter is key to getting good results. Different types suit different needs based on several factors:

- Material Compatibility: Each laser type is better for certain materials. Knowing these helps you pick the right machine.

- Application Suitability: Some lasers fit industrial uses needing high precision or mass production, while others are perfect for creative hobbies.

- Budget Considerations: Prices vary greatly across types. Understanding what each type offers helps you make smart buying decisions without spending too much.

Picking the right laser cutter helps improve efficiency and the quality of your work—whether crafting unique items or handling larger production tasks.

Key Categories of Laser Cutters Explained Briefly

Knowing about the main types of laser cutters can help buyers make informed choices:

| Type | Best For | Applications |

|---|---|---|

| CO2 Lasers | Non-metals (wood, acrylics) | Wooden projects, acrylic designs |

| Fiber Lasers | Metals (stainless steel, aluminum) | High-speed metal fabrication |

| UV Lasers | Delicate materials requiring high precision | Micromachining or circuit board etching |

CO2 lasers excel at cutting non-metal materials like wood and fabric. They produce smooth edges with minimal burning. Fiber lasers are great for metals due to their speed and efficiency. UV lasers offer high accuracy for intricate tasks involving sensitive components like electronic circuits.

By understanding these differences among laser cutters—and their strengths—you can choose a machine that fits your project needs perfectly.

CO2 Laser Cutters

How Does a CO2 Laser Cutter Work?

A CO2 laser cutter uses gas-based laser technology, mainly carbon dioxide, to create a powerful laser beam. The process kicks off when electricity excites a gas mixture inside a sealed tube. This reaction produces a high-energy light beam that is focused through mirrors onto the material being cut or engraved. The laser wavelength of about 10.6 micrometers is particularly good at cutting non-metal materials because of how well those materials absorb the light.

The actual cutting happens when the focused beam moves across the surface of the material at different speeds and strengths. This allows it to either cut through or engrave designs into various substrates. As the laser interacts with the materials, it generates heat that vaporizes them along a precise path, which is controlled by a computer.

What Materials Can a CO2 Laser Cutter Process?

CO2 laser cutters are well-known for their ability to work with many non-metal materials. Here’s what they can handle:

- Wood: Perfect for detailed cuts and engravings.

- Acrylic: Provides smooth edges, making it great for displays and signage.

- Leather: Enables intricate designs without damaging the fibers.

- Plastic: Useful for creating prototypes and custom parts.

This versatility makes these cutters popular among hobbyists and small businesses looking to create personalized items or custom designs.

Advantages & Limitations of CO2 Lasers

Advantages

CO2 lasers stand out as affordable options among various laser cutters available today. Their versatility opens doors to numerous industrial applications—from crafting decorative items to manufacturing larger components. Plus, they handle both cutting and engraving tasks effectively, making them valuable tools in makerspaces.

Limitations

On the flip side, there are some drawbacks to consider when using CO2 lasers. They struggle with cutting reflective metals like aluminum or copper; for this, specialized equipment like fiber lasers is often necessary. Additionally, ensuring proper ventilation during operation is crucial due to fumes produced while processing certain materials like plastics or wood.

Popular Applications for CO2 Lasers

CO2 lasers are widely used across different industries because they deliver high-quality results quickly and efficiently. Some common applications include:

- Personalized Products: Items like custom gifts or promotional materials made from wood and acrylic.

- Decorative Pieces: Examples include photo frames and intricate designs.

- Signage: These lasers help enhance branding efforts for small businesses or events.

By understanding how a CO2 laser cutter works and what it can do, individuals can make better decisions about incorporating this technology into their projects—whether they’re aiming for personal creativity or commercial production needs.

How Does a Fiber Laser Cutter Work?

Fiber laser cutters use solid-state technology to provide efficient and precise cutting for various tasks. They generate light through rare-earth elements like ytterbium or neodymium that are added to optical fibers. This light is amplified within the fiber and then directed to the workpiece through advanced optics. This method enables high-speed laser cutting with excellent accuracy, making it ideal for many applications.

What Materials Can a Fiber Laser Cutter Process?

Fiber laser cutters are great at cutting metals such as stainless steel and aluminum. Their focused beam quality allows them to make clean cuts while minimizing heat-affected zones. They can also handle some plastics but are not as effective with non-metal materials compared to CO2 lasers.

| Material Type | Cutting Capability |

|---|---|

| Stainless Steel | Excellent |

| Aluminum | Excellent |

| Plastics | Moderate |

| Non-Metal Materials | Limited (compared to CO2 lasers) |

Advantages & Limitations of Fiber Lasers

Advantages:

- Speed and Precision: Fiber lasers cut quickly while maintaining high accuracy, which is perfect for detailed designs.

- High Efficiency: They use less power than other types of laser cutters, lowering operational costs over time.

- Minimal Maintenance: With fewer moving parts, these machines require less upkeep.

Limitations:

- Initial Investment Cost: The upfront cost is generally higher than other options available.

- Limited Versatility: While they excel at metal cutting, their performance with non-metal materials can be restricted.

Popular Applications for Fiber Lasers

Fiber lasers are used in various industries where precision is key. Common applications include:

- Automotive Manufacturing: Producing detailed components that need exact specifications.

- Electronics Production: Speed and accuracy are essential for small parts.

- Signage Production: Ideal for creating detailed signs quickly without losing quality.

- Custom Design Work: Great for projects that blend creativity with precision.

Understanding how fiber laser cutters work helps you appreciate their advantages and limitations when choosing the right type of laser cutter for your needs.

UV Laser Cutters: Micromachining and Fine Detail Work

How Does a UV Laser Cutter Work?

A UV laser cutter uses excimer lasers. These lasers produce high-energy photons at a short wavelength of around 355 nm. This ultraviolet technology allows for precise cutting and engraving of delicate materials. The energy is delivered in concentrated bursts, which helps avoid heat damage to the material. With minimal heat diffusion, the heat-affected zone is very small. This makes UV laser cutters perfect for sensitive substrates that might be harmed by heat.

What Materials Can a UV Laser Cutter Process?

UV laser cutters can work with several types of materials, mainly polymers and specialized plastics. Here’s a list of materials commonly processed:

- Acrylics

- Polycarbonate

- PETG (glycol-modified polyethylene terephthalate)

- Some rubber or silicone products

These machines handle material thicknesses from thin films to a few millimeters, depending on the polymer type.

Advantages & Limitations of UV Lasers

Advantages:

- Extreme Precision: The small heat-affected zone allows for detailed designs without damaging the material.

- Ideal for Intricate Designs: They are well-suited for micro-machining, producing essential detailed patterns.

Limitations:

- Lower Power Output: Compared to CO2 or fiber lasers, UV lasers often have less power.

- Higher Initial Cost: Purchasing equipment can be expensive due to advanced technology needs.

- Material Compatibility Issues: Not all materials process well; some metals may not give good results with UV lasers.

Popular Applications for UV Lasers

UV laser cutters are widely used in micromachining tasks like circuit board etching and creating intricate patterns on various surfaces. Their ability to produce high-resolution engravings makes them valuable in industries such as electronics manufacturing and custom design projects. For example, they are often used to craft precise designs on medical devices or decorative items where accuracy is crucial.

Nd:YAG/Nd:YVO Laser Cutters

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) and Nd:YVO (Neodymium-doped Yttrium Orthovanadate) lasers are solid-state laser cutters. They use rare-earth elements to create a focused beam of light. These lasers work well at wavelengths around 1.06 µm and are great for precision tasks like metal cutting and engraving.

Working Principle

The Nd:YAG/Nd:YVO lasers work by exciting neodymium ions within their crystal structure. This is done using flash lamps or diodes. The result is a powerful beam that can penetrate metals deeply without causing much heat distortion. This pulsed technology allows for high-precision cutting across various materials.

Suitable Materials

These laser cutters can process a variety of metals, such as:

- Stainless steel

- Aluminum

- Brass

- Copper

While they can also cut some plastics, they shine when working with metals, making them ideal for industrial uses where durability is key.

Advantages & Disadvantages

Advantages:

- High power output leads to fast cutting speeds.

- Excellent precision allows for intricate designs and detailed engravings.

Disadvantages:

- They require a higher initial investment compared to CO2 laser options.

- Limited flexibility with non-metal materials; they mainly focus on metalworking tasks.

Popular Applications

Industries like aerospace and automotive manufacturing rely on Nd:YAG/Nd:YVO lasers. They provide the precision needed for high-quality parts, making them essential tools in settings where accuracy matters most.

Diode Laser Cutters

Diode laser cutters are another type of solid-state technology. They’re mostly used for engraving rather than heavy cutting because they typically have lower power levels.

Working Principle

Diode lasers generate light by passing an electric current through semiconductor material. This process is efficient but usually results in lower intensity compared to other lasers like fiber or CO2 types. Continuous wave (CW) diode technologies allow steady output but limit the depth and speed during operations.

Suitable Materials

These machines do well with thin materials, like:

- Plastics

- Wood

However, they struggle with thicker materials or metals due to their limited power output capabilities. They excel in applications that require detailed engravings on lighter substrates.

Advantages & Disadvantages

Advantages:

- Their compact size makes diode laser cutters great for desktop use.

- Generally more affordable than higher-powered alternatives available today.

Disadvantages:

- Their ability to handle thick or dense materials is quite limited, which restricts usage scenarios significantly.

Popular Applications

You’ll find diode laser cutters in hobbyist settings, often used for crafting personalized items from wood or acrylics. They’re perfect for projects that need fine details without requiring heavy-duty performance.

Factors to Consider When Choosing a Laser Cutter

When you think about getting a laser cutter, a few things really matter. Knowing the types of laser cutters can help you make the best choice for your needs.

Types of Laser Cutters

- CO2 Laser Cutter: These are great for cutting and engraving non-metal materials like wood, acrylic, glass, and leather. CO2 lasers are versatile and produce high-quality cuts with smooth edges.

- Fiber Laser Cutter: Perfect for cutting metals such as stainless steel and aluminum. Fiber lasers are faster than CO2 lasers and require less upkeep due to their solid-state design.

- Diode Laser Cutter: These are often used for smaller projects or DIY tasks. They’re good for engraving various materials but not as strong when it comes to cutting.

- UV Laser Cutter: Best for marking plastics without causing damage from heat. UV lasers provide precise engravings on delicate materials that heat may ruin.

- Nd:YAG Laser Cutter: Industrial machines that can cut thick metal sheets with accuracy but usually cost more than other options.

- Industrial vs Desktop vs Portable Handheld Cutters:

- Industrial laser cutters are made for heavy use in factories.

- Desktop models are meant for hobbyists or small businesses needing a compact option.

- Portable handheld cutters offer flexibility but may lack the power of bigger machines.

Material Compatibility

Each type of laser cutter works best with certain materials:

- CO2 lasers handle organic materials like wood and some plastics well.

- Fiber lasers cut metals efficiently.

- Diode lasers excel at light engraving tasks across various surfaces.

- UV lasers focus on sensitive items like specific plastics without melting them.

Knowing which cutter works with your material will help you pick the right machine for your projects.

Budget Considerations

The cost of laser cutters varies widely:

- Entry-level desktop models can start from around $200 to $500,

- Mid-range CO2 systems usually fall between $1,000 to $5,000,

- High-end industrial fiber systems can go over $10,000 based on features and capabilities.

Look at your budget against these options to find what fits best while considering long-term costs like maintenance and supplies.

In choosing a laser cutter—whether it’s a handy CO2 model or an efficient fiber system—think about what materials you’ll be using along with your budget to find the perfect match.

Decision Tree for Selecting a Laser Cutter

When trying to figure out the best laser cutter for you, using a decision tree can really help clarify things.

- What do you plan to cut or engrave?

- Metals? A fiber laser might be best.

- Wood or acrylic? Consider a CO2 laser.

- How often will you use it?

- Daily in a workshop? Look into an industrial model.

- Just for occasional home projects? A desktop model should work fine.

- What’s your budget?

- Under $500? Check out entry-level options.

- Over $5,000? You might want to explore advanced models with more features.

Following these questions can guide you through the process of selecting the right machine.

Laser Cutter Safety and Maintenance

Laser Safety Precautions

When you use a laser cutter, safety is super important. One key step is wearing the right laser safety glasses. These glasses guard your eyes from harmful light that can cause serious damage. Choose glasses rated for your laser’s wavelength to ensure full protection.

Good ventilation systems are also necessary during cutting. Lasers produce fumes from various materials, which can be bad for your health if inhaled. A strong fume extraction system helps keep the air clean, making your workspace safer.

Fire safety measures must not be ignored. Always keep a fire extinguisher nearby when using the laser cutter. Flammable materials can easily catch fire from the heat produced by lasers. Store any combustible items far away from the machine to reduce risk.

Laser Cutter Maintenance

To keep your laser cutter working well, regular maintenance is essential. Establishing consistent cleaning routines is a must. Regularly cleaning lenses and mirrors prevents buildup that could hurt cutting quality or cause overheating.

You should also take preventative measures like checking alignment and calibration before each use. Misalignment may lead to inaccurate cuts or engravings, wasting both time and materials.

Learn basic troubleshooting techniques to fix common problems. If you notice uneven edges in your cuts, this could mean lens contamination or misalignment needs immediate attention.

Frequently Asked Questions

What types of materials can I cut with different laser cutters?

- CO2 Laser Cutters: Best for wood, acrylic, leather, and some plastics.

- Fiber Laser Cutters: Excellent for stainless steel, aluminum, and brass.

- UV Laser Cutters: Ideal for polymers, such as PETG and polycarbonate.

- Nd:YAG Lasers: Suitable for a wide range of metals and some plastics.

How does cutting speed vary among different laser types?

Cutting speed depends on the type of laser used. Fiber lasers typically offer higher cutting speeds due to their efficient beam quality. CO2 lasers may cut non-metals at moderate speeds. UV lasers tend to be slower but excel in precision.

What is the importance of laser power when choosing a cutter?

Laser power affects the cutter’s efficiency and capability. High-power CO2 lasers can handle thicker materials effectively. Fiber lasers often require less power but still achieve fast cuts in metals. Knowing your material thickness helps determine necessary wattage.

How do I determine the right laser cutter size for my needs?

When selecting a laser cutter, consider its dimensions and weight. Larger machines often accommodate bigger materials or projects but require more space. Smaller desktop models suit hobbyists or limited workspaces.

What are common issues faced with laser cutters?

Users often encounter problems like misalignment or uneven cuts. Dust buildup on lenses can affect precision. Regular maintenance checks ensure optimal performance.

How does the cutting depth vary with different laser types?

Cutting depth varies by material and laser technology. CO2 lasers excel at cutting through wood up to several inches thick, while fiber lasers effectively cut metal sheets several millimeters deep.

Can I engrave with all types of laser cutters?

Yes, you can engrave with each type of laser cutter. However, some perform better than others depending on the material. CO2 lasers provide high-quality engravings on wood and acrylic, while UV lasers excel at fine details on sensitive substrates.

Additional Information about Laser Cutters

Key Considerations When Selecting a Laser Cutter

- Material Compatibility: Know what materials you will be using.

- Power Requirements: Assess wattage needs based on thickness.

- Cutting Depth: Consider how deep you need to cut specific materials.

- Precision Needs: Different applications require varying degrees of detail.

- Budget Constraints: Determine your spending limit early on.

Laser Cutter Maintenance Tips

- Clean lenses regularly to maintain clarity.

- Check alignment before starting new projects.

- Inspect cooling systems for effective operation.

Understanding Laser Cutting Technology

- Laser Wavelengths: Different wavelengths target specific materials.

- Beam Diameter: Affects cutting resolution and detail level.

- Efficiency Factors: Higher efficiency reduces operational costs over time.

Future Trends in Laser Cutting

- Growing automation in industrial settings enhances productivity.

- Innovations focus on improving precision and speed.

- The market anticipates broader applications across various industries.

Understanding these factors can help you choose the right equipment for your specific needs while staying informed about industry trends.

Related Topics

- types of laser engraving machines

- types of laser cutting materials

- types of laser applications

- types of laser safety equipment

- types of laser cutter maintenance

- types of laser cutter software

- types of laser cutter brands

- types of industrial laser cutters

- types of desktop laser cutters

- types of portable laser cutters

Types of Laser Cutters: A Guide to CO2, Fiber, and Solid-State Lasers