Types of laser cutting include CO2 and fiber lasers, each best for different materials. This guide explores various laser types, their applications, and best practices.

What is Laser Cutting?

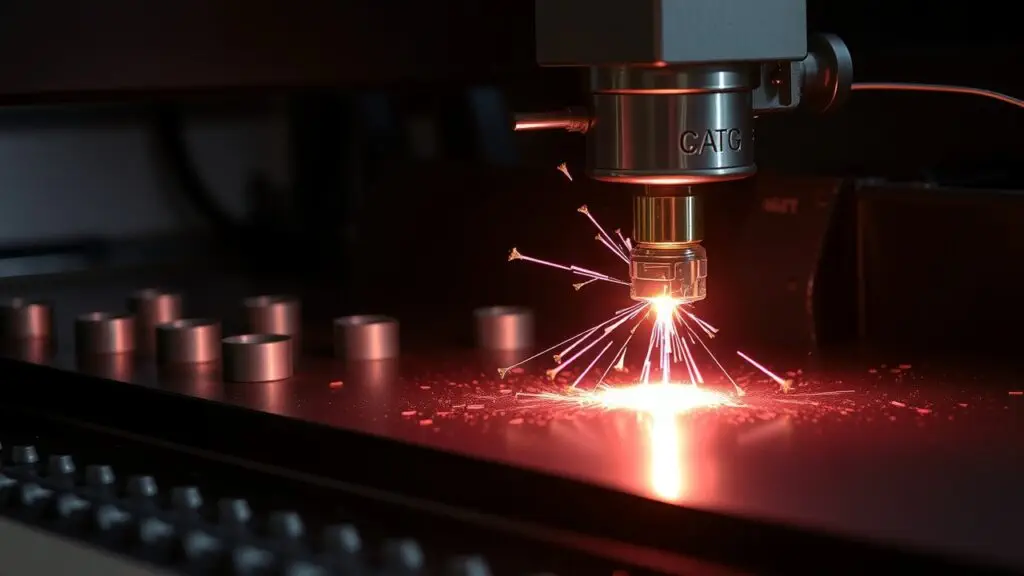

Laser cutting is a process that uses a focused beam of light to cut through different materials. The laser interacts with the material, either melting or vaporizing it. This technique allows for high precision and speed, making it perfect for modern manufacturing. Industries like automotive, aerospace, and electronics rely on this method for creating detailed designs while minimizing waste.

Why Are There Different Types of Laser Cutting?

Different lasers are important because they work better on specific materials. For example, CO2 lasers are great for cutting non-metal materials like wood and acrylic. They have a longer wavelength that these materials absorb easily. On the other hand, fiber lasers are ideal for metals due to their high energy density. This allows them to cut through thicker pieces more effectively.

When choosing a laser type, the material’s thickness, reflectivity, and thermal conductivity matter a lot. For instance, fiber lasers can handle reflective metals like aluminum without causing too much heat distortion. In contrast, CO2 lasers might have difficulty with those metals.

Other considerations include cost and the quality of the finish needed. Some projects might need smoother edges than others, which can influence which laser is selected.

Overview of Main Laser Types Used in Cutting

Here’s a quick look at the main types of lasers used in cutting:

| Type | Best Suited For | Characteristics |

|---|---|---|

| CO2 Lasers | Non-metals (wood, acrylic) | Good efficiency; produces decent cut quality but slower compared to fiber lasers |

| Fiber Lasers | Metals (steel, aluminum) | Fast processing; energy-efficient; requires less maintenance |

| UV Lasers | Microscopic tasks | Perfect for delicate cuts on thin films or tiny components due to short wavelengths |

| Nd:YAG Lasers | Various applications | Versatile solid-state option; works well with both metal and plastic |

Each laser type has strengths: CO2 lasers offer smooth finishes on softer materials while fiber lasers provide quick processing for high-volume needs. Knowing these differences helps businesses choose the right technology based on what they need most.

CO2 Laser Cutting Explained

How Does CO2 Laser Cutting Work?

CO2 laser cutting uses a gas laser to create a powerful beam of light. The process starts when electrical energy is applied to a mix of carbon dioxide and other gases. This creates plasma, which generates infrared light. The laser beam is then amplified and directed through mirrors to the material being cut.

The focused laser beam interacts with the material through a thermal process. When the laser hits the surface, it heats up quickly. This causes the material to either melt or vaporize based on its properties. This method allows for detailed designs and smooth cuts in various materials.

Best Materials for CO2 Lasers

CO2 lasers can cut or engrave many types of materials well. Here are some of the best ones:

- Wood: Great for crafts since it’s easy to cut.

- Acrylic: Cuts smoothly; it’s popular for signs.

- Plastic: Different plastics can be processed without much distortion.

- Leather: Perfect for detailed engravings and cutting patterns.

- Paper: Ideal for making intricate designs in crafts or packaging.

These materials take advantage of CO2 lasers’ ability to create fine details while keeping production speed high.

Applications Where CO2 Lasers Excel

CO2 lasers are widely used in various industries because they are so adaptable. Key applications include:

- Industrial Laser Applications: They are used in manufacturing for precise part fabrication.

- Sign Making Laser Cutting: They enable quick production of custom signs with clear graphics.

- Fabric Cutting for Clothing Production: They are essential in fashion design, where accuracy matters.

- Engraving Designs on Non-Metals: Commonly used to personalize items like awards or gifts by etching detailed images onto surfaces like glass or wood.

These applications show how effective CO2 lasers are at producing high-quality results across different fields.

Advantages & Limitations

When thinking about different laser cutting methods, it’s useful to look at both advantages and limitations of CO2 lasers:

Advantages:

- A cost-effective entry-level option compared to advanced systems like fiber lasers.

- Performs well on non-metallic materials, making them perfect for many creative projects.

Limitations:

- Generally slower than fiber options when cutting metals.

- Less effective on reflective metals unless specific techniques are used, such as applying special coatings.

Knowing these factors helps users decide if CO2 laser cutting fits their project needs across various industries.

Fiber Laser Cutting Essentials

How Do Fiber Lasers Function?

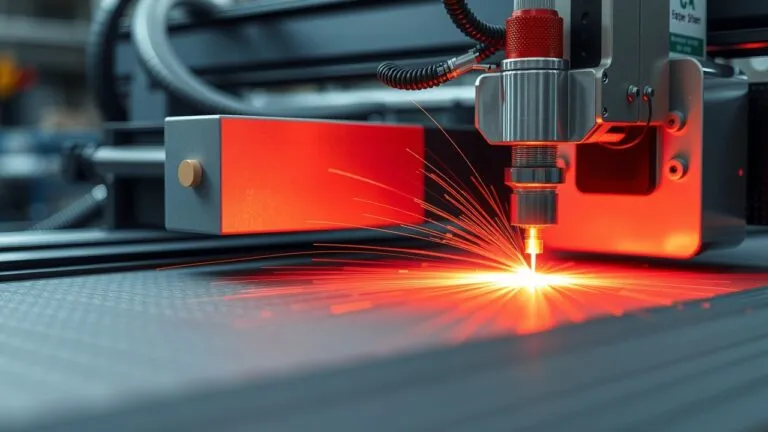

Fiber lasers are solid-state lasers that use special optical fibers filled with rare-earth elements, like ytterbium. This design lets them create powerful laser beams efficiently. The process starts with diode-pumped generation, which makes wavelengths around 1 micrometer (μm). These wavelengths work really well for cutting metals because of how they interact with reflective surfaces.

Fiber lasers also have great beam quality. They can focus tightly on the material, which leads to precise cuts and less heat damage around the edges. Plus, since they’re solid-state, they need less maintenance compared to gas-based systems, like CO2 lasers. Their compact size makes them perfect for tight spaces in various industries.

Metal-Specific Focus Details

Fiber laser cutting is fantastic for different types of metals, including stainless steel, aluminum, and titanium. Each metal has its own challenges, but fiber lasers tackle them well by delivering energy right where it’s needed. Here’s how these metals are used:

| Metal Type | Applications |

|---|---|

| Stainless Steel | Found in kitchen tools and medical equipment due to its rust resistance. |

| Aluminum | Popular in car parts because it’s light yet strong. |

| Titanium | Used in aerospace projects for its impressive strength-to-weight ratio. |

In fields like aerospace and automotive construction, automated designs take advantage of fiber laser cutting technology to produce items quickly while keeping high precision to meet strict industry standards.

Advantages of Fiber Laser Cutting

There are many good reasons to choose fiber laser cutting over older methods like CO2 or UV lasers:

- Speed: Fiber lasers can cut through thicker materials quicker than many alternatives.

- Efficiency: They use less energy while producing better output.

- Precision: The focused beam gives clean cuts with little thermal damage.

- Versatility: They can handle a range of materials besides metals—though metals are their main focus.

These benefits make fiber laser cutting a smart choice in manufacturing settings that want cost-effective solutions without losing quality.

Limitations of Fiber Laser Cutting

Even though fiber lasers have many advantages, they do have some limits:

- Material Compatibility Issues: They excel at cutting metals but can struggle with non-metal materials like plastics or wood when compared to CO2 systems.

- Initial Investment Costs: The best fiber laser machines can be pricey upfront, which may hold back some smaller businesses from jumping in.

- Maintenance Needs: While they’re low-maintenance compared to gas systems, keeping them running well still requires regular care.

Knowing these limits helps businesses figure out if this method fits their specific needs.

Applications Across Industries

Fiber lasers aren’t just for standard metalwork; they shine in lots of different areas:

- In electronics: They allow for precision cuts needed for complex circuit boards and components.

- Artistic work: Artists can use custom laser-cutting services to achieve fine details that traditional methods can’t match.

- Prototyping: Quick prototyping relies on high accuracy and fast production—features that fiber lasers provide well.

Overall, the flexibility of fiber lasers makes them valuable tools in both creative projects and industrial environments where precision is key.

UV Laser Cutting: Microscopic Precision

How Does UV Laser Cutting Work?

UV laser cutting uses excimer laser technology. This method creates a strong beam with a wavelength of about 355 nm. This specific wavelength is key because it helps the laser interact precisely with materials at a tiny level. When the laser hits materials, it makes them absorb energy and turn into gas or vapor. This happens without causing much heat damage around the cut area. So, you get very fine cuts and detailed designs that other lasers can’t achieve easily.

Materials Suitable for UV Laser Cutting

The precision of UV lasers is great for various materials that need careful detail. Common materials for cutting include:

- Polymers

- Thin films

- Glass

- Certain plastics

These materials take advantage of the high-resolution abilities of UV lasers. This makes them perfect for areas like micromachining and making medical devices where accuracy is very important.

Applications Where UV Lasers Excel

In industries like semiconductor manufacturing and medical device production, UV lasers are crucial. They can create clean cuts while minimizing heat impact on materials. They’re also used in producing fine artwork where intricate patterns matter a lot. Visuals can show how these lasers help make complex designs in microelectronics or delicate components in healthcare technologies.

Advantages & Limitations

Using UV laser cutting comes with some notable advantages:

- Precision: It offers extremely high precision.

- Cut Quality: The cuts are clean with little thermal damage.

However, there are some downsides too:

- Higher costs compared to CO2 or fiber lasers.

- Power limitations when cutting thicker materials.

While considering different laser cutting technologies, like CO2 and fiber lasers, it helps to understand how ultraviolet (UV) lasers work. They offer unique strengths that make them fit for tasks needing microscopic precision.

Other Laser Cutting Types (Optional, but recommended for comprehensiveness)

Nd:YAG Laser Cutting

Nd:YAG lasers, which stand for Neodymium-doped Yttrium Aluminum Garnet lasers, are solid-state lasers. They are well-known for being efficient and versatile in cutting various materials. Unlike CO2 and fiber lasers, Nd:YAG lasers use a crystal medium to produce laser light. This design allows them to create high-intensity beams that can cut through metals and ceramics effectively.

One big plus of Nd:YAG laser cutting is that it can work with reflective materials like copper and brass. These metals can be tricky for other lasers to handle. Also, they provide great precision and control during the cutting process. You will find common uses in industries such as aerospace, automotive manufacturing, medical devices, and jewelry making.

However, there are downsides too. The initial cost for Nd:YAG systems can be higher compared to CO2 systems because of the technology’s complexity. While they do well with metal cutting, their performance on thicker materials might not match that of fiber lasers.

Materials Suitable for Nd:YAG Laser Cutting:

- Metals

- Ceramics

Common Applications:

- Aerospace components

- Medical devices

Diode Laser Cutting

Diode lasers are a compact option among low-power laser technologies. They use semiconductor diodes as their light source, making them small and easy to integrate into machines where space is tight.

These lasers are great for plastic fabrication due to how well they interact with polymer materials. Diode lasers give good quality cuts and are energy-efficient compared to larger systems. But they have limitations; they work best on thinner sheets rather than heavy-duty materials.

Materials Commonly Processed with Diode Technology:

- Plastics

- Thin films

- Textiles

Diode cutters might not take the place of more powerful options like CO2 or fiber lasers in every situation. Still, they shine in specific niches because of their affordability and user-friendly design.

Considerations for Less Common Laser Types

There are also less common types of lasers that might suit unique needs:

- Gas Lasers: These are often used when large beam sizes are required.

- Crystal Lasers: Known for high power output, they’re good for precise tasks but usually come at a higher cost.

- High-Power Lasers: Perfect for thick materials needing deep penetration.

- Low-Power Lasers: Best suited for delicate jobs where heat management is key—like stealth dicing in electronics manufacturing.

Each type has its own features that make it suitable depending on the material properties or specific outcomes needed in precision tasks like reactive cutting or managing thermal stress cracking during complex fabrications.

By understanding these variations, users can pick the right system that meets their project needs without overspending on features they won’t use.

Choosing the Right Laser Cutting Technology: A Step-by-Step Guide

Factors to Consider

When picking a laser cutting technology, it’s helpful to think about several important factors. These will help you find the best method for your project.

- Material Type: Different lasers work better with different materials. For example, CO2 lasers are great for cutting non-metal stuff like wood and acrylic. On the other hand, fiber lasers are better at cutting metals like steel and aluminum.

- Thickness: The thickness of your material is key. Thicker materials often need more powerful machines or specific types of lasers that can cut deeper while keeping quality high.

- Precision: If you need detailed designs or exact measurements, look for a laser known for its precision. UV lasers usually offer high accuracy, especially on delicate materials.

- Budget: Your budget will affect which technology you can afford. Fiber lasers might cost more upfront but often save money in the long run with lower operational costs compared to CO2 lasers.

- Volume: Think about how many pieces you’ll need to cut regularly. Some technologies work better for high-volume production since they are faster and more efficient.

- Desired Finish: The finish you want after cutting is also important. Some methods leave smoother edges, which can change how much extra work you need after cutting, depending on your application needs.

By looking closely at these factors, you can choose a laser cutting method that fits your project well.

Decision-Making Process

To make choosing easier, a flowchart or decision tree can help guide you based on your project’s needs:

- Start by identifying the main material.

- Figure out how thick that material is.

- Consider if precision matters.

- Set a budget range.

- Decide if this is a one-time job or part of regular production.

This approach makes it clearer to choose from the different laser cutting technologies available today.

Material Compatibility Charts

Knowing which materials match with each laser type helps when planning projects involving metal fabrication or non-metal applications:

| Laser Type | Best Suited Materials | Typical Applications |

|---|---|---|

| CO2 Laser | Wood, Acrylic, Plastics | Sign making, engraving |

| Fiber Laser | Steel (mild & stainless), Aluminum | Industrial parts manufacturing |

| UV Laser | Glass, Ceramics | Electronics components |

These compatibility charts serve as visual guides to see what works best based on your project’s needs and desired outcomes in both metal and non-metal areas.

Safety and Best Practices

Laser Safety Precautions

Safety comes first when using laser cutting tools. Proper laser safety precautions are key to keeping everyone safe. First, always wear eye protection. Specialized goggles can shield your eyes from harmful beams and reflections.

Good ventilation is also important. Lasers can create fumes that may be dangerous to breathe in. Ensure your workspace has enough airflow to reduce health risks. Operators must know the relevant laser safety regulations, which differ based on location. These rules stress the importance of proper equipment upkeep and necessary training.

Handling materials carefully is crucial too. Some materials can catch fire or release toxic gases when cut with lasers. Check the material data sheets for specific handling instructions before you start cutting.

Material Preparation and Design Considerations

Before you begin, make sure you’ve done proper material preparation for laser cutting. This means your materials should be clean—free from dust, grease, or anything that might interfere with a good cut. Using the right cleaning agents can help with this.

Design matters too! Consider things like kerf width—the amount of material removed during cutting. This is vital for ensuring your final dimensions are accurate. Knowing how different lasers work with various materials helps in choosing designs that save waste while improving efficiency.

Parameter Optimization

To get the best results in laser cutting, focus on adjusting settings like power and speed based on what you are cutting. Higher power usually means faster cuts but can create excess heat if not monitored carefully.

Speed also impacts your cuts; going slower often leads to cleaner edges but takes more time overall. Finding a balance between these settings helps meet project goals while maintaining quality across various types of laser cutting tasks.

FAQs about Types of Laser Cutting

What is laser cutting tolerance?

Laser cutting tolerance refers to the allowable variation in the dimensions of cut parts. It varies by material and laser type. CO2 lasers generally achieve tighter tolerances on non-metal materials.

What is cutting kerf?

Cutting kerf is the width of material removed during the cutting process. It affects how accurately pieces fit together. Different lasers have different kerf sizes.

What are 1:1 minimum hole sizes in laser cutting?

1:1 minimum hole size indicates the smallest diameter hole a laser can cut without creating excessive heat or deformation. This often applies to thicker materials.

How does sheet metal laser cutting differ from thick metal laser cutting?

Sheet metal laser cutting typically uses higher speeds for thinner materials. Thick metal laser cutting requires more power and slower speeds for quality cuts.

What factors affect laser cutting cost per part?

Costs include material type, thickness, and complexity of the design. Operating costs also contribute, such as maintenance and energy use.

How does lead time influence laser cutting projects?

Lead time indicates how long it takes to complete a project. Shorter lead times often require more resources or prioritization.

Additional Insights into Laser Cutting Technologies

- Laser Cutting Equipment: Different machines suit specific applications. Understanding machine capabilities helps select the right one.

- Purchasing vs. Leasing a Laser Cutter: Consider budget and project volume when deciding. Leasing offers flexibility for small operations.

- Laser Cutting Regulations: Compliance with safety standards ensures worker protection. Familiarize yourself with local laws before operating.

- Laser Cutting Quality Control: Regular checks maintain high-quality output. Implementing quality control measures prevents defects.

- Laser Cutting Safety Training: Ensure operators receive proper training on handling machines safely. Training reduces workplace accidents significantly.

- Laser Cutting Business Opportunities: The growing demand for customized products opens new markets. Explore niches in industries like automotive and electronics.

- Laser Cutting Environmental Impact: Evaluate the waste produced during cutting processes. Incorporating sustainable practices benefits both business and environment.

By addressing these key points, individuals and businesses can make informed decisions about their laser cutting needs while optimizing processes for efficiency and safety.

Related Topics

- Types of Laser Cutting Machines

- Types of Laser Cutting Materials

- Types of Laser Cutting Applications

- Types of Laser Cutting Processes

- Types of Laser Cutting Safety Precautions

- Types of Laser Cutting Design Considerations

- Types of Laser Cutting Finishes

- Types of Laser Cutting Businesses

- Types of Laser Cutting Services

- Types of Laser Cutting Software

- Types of Laser Cutting Maintenance

- Types of Laser Cutting Safety Equipment

Types of Laser Cutting: CO2, Fiber, and More